Different Types of Cranes and Their Key Uses in Modern Construction

In modern construction, a wide range of cranes are used, each designed for a specific lifting task. Some handle heavy steel beams, others position bridge components, and many move materials across complex sites. The design of every crane reflects its purpose; some remain fixed in place, such as tower cranes used on high-rise projects, while others provide full mobility and rapid setup, like mobile and crawler cranes used for infrastructure and civil works.

Cranes today also integrate advanced safety systems, load-monitoring technology, and precise hydraulic control to improve efficiency and meet strict Australian lifting standards. With such a diverse fleet operating across commercial, industrial, mining, and infrastructure projects, selecting the right crane is critical to productivity and site safety. Knowles Cranes recognises the importance of understanding when and why each type of crane should be utilised.

This guide offers a comprehensive overview of the primary construction cranes, their key functions, and the specific conditions under which they perform optimally.

Classification of Cranes

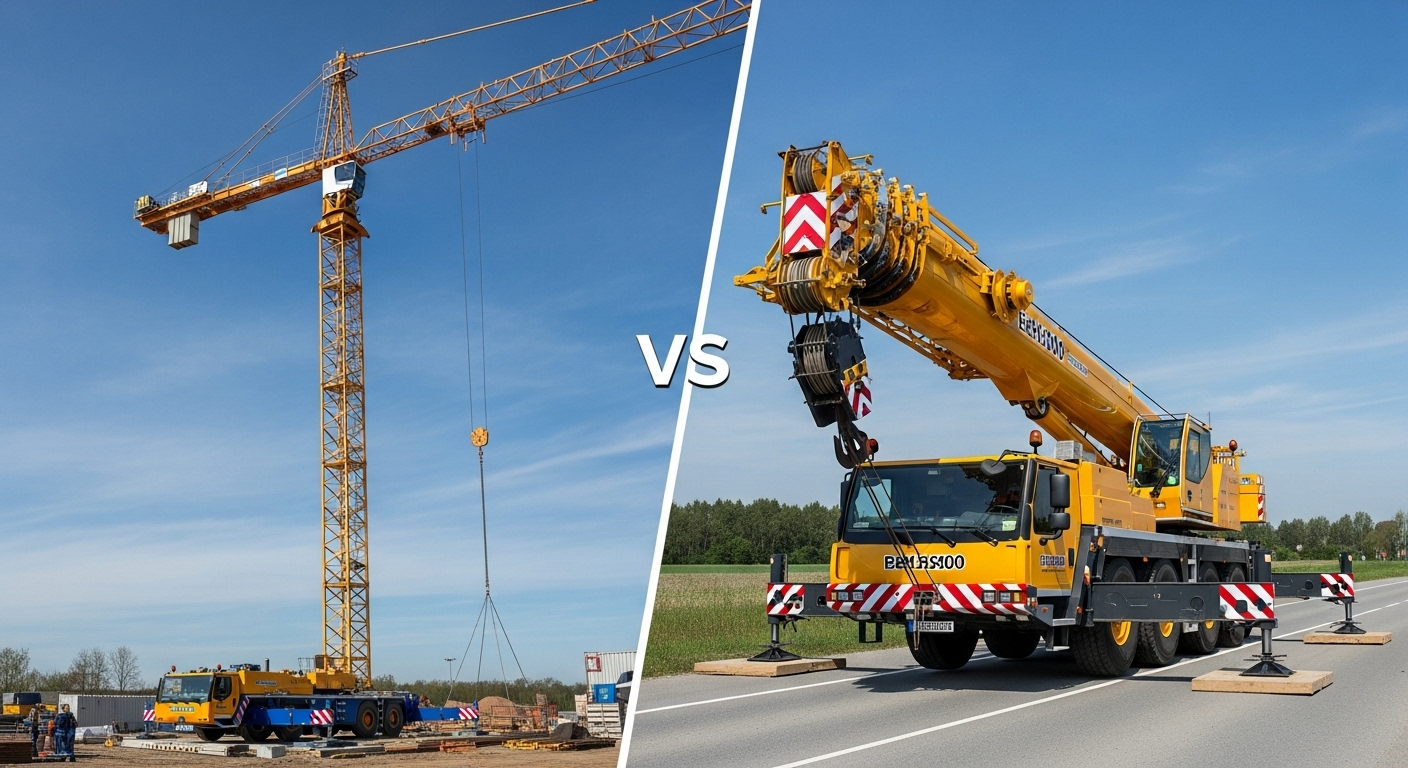

In construction, cranes are primarily categorised into two main groups: fixed cranes and mobile cranes.

Fixed Cranes

These cranes are installed in a single position and stay there for the entire project. Examples include tower cranes, bridge cranes, and gantry cranes. They provide great height and lifting power, but cannot be moved once set up. They are ideal for long-term projects such as high-rise buildings or large infrastructure work.

Mobile Cranes

These cranes are built on wheels or tracks, allowing them to travel between or within job sites. Common types include all-terrain, rough-terrain, crawler, and truck-mounted cranes. Their flexibility makes them perfect for short-term or multiple-site construction projects.

Cranes can also be slewing, where the boom rotates, or non-slewing, where the boom stays fixed, like in pick-and-carry cranes. Understanding these differences helps project teams choose the right crane for each site's layout and lifting requirements.

Comparison of the Main Types of Cranes Used in Construction

| Crane Type | Main Use | Typical Capacity | Key Advantage | Main Limitation |

|---|---|---|---|---|

| Tower Crane | High-rise and large commercial buildings | 5–300 tonnes | Excellent height and reach; ideal for tall structures | Costly and time-consuming to set up and remove |

| Crawler Crane | Bridges, power plants, wind farms, heavy infrastructure | 80–1000 tonnes | Very high lifting power and stable base | Slow to move; must be dismantled for transport |

| All-Terrain Crane | Roadworks, bridge projects, urban and rural construction | 20–300 tonnes | Can travel on roads and handle rough terrain | Needs a wide setup area; limited off-road performance |

| Rough-Terrain Crane | Mines, oil fields, and off-road construction sites | 20–80 tonnes | Compact design and strong off-road mobility | Not suitable for long road travel |

| Truck-Mounted Crane | Logistics, utilities, quick material loading and unloading | 10–20 tonnes | Fast to move and easy to set up | Lower capacity and less stability |

| Pick-and-Carry (Franna) Crane | Industrial yards, workshops, tight urban spaces | Up to 25 tonnes | Can drive with a load on site; saves setup time | Smaller capacity and higher tipping risk |

| Floating Crane | Harbours, bridges, offshore lifting | 25–1000+ tonnes | Works where land access is not possible | Weather-dependent; complex marine setup |

Selecting the Right Crane

Selecting the right crane depends on several key factors. The decision should consider project size, ground conditions, required height, and the frequency of crane movement.

| Factor | What to Consider |

|---|---|

| Load Capacity | Choose a crane with a rated capacity that covers your heaviest lift. |

| Height and Reach | Tower cranes suit tall structures; mobile cranes work better for wider reach. |

| Site Conditions | Crawler cranes perform best on soft ground; rough-terrain cranes handle uneven sites. |

| Project Duration | Fixed cranes are ideal for long-term projects; mobile cranes fit short or multi-site work. |

| Access and Mobility | Truck-mounted and Franna cranes are perfect for quick setup and relocation. |

| Pick-and-Carry (Franna) Crane | Industrial yards, workshops, tight urban spaces |

| Floating Crane | Harbours, bridges, offshore lifting |

A well-planned site always matches the type of crane to the job’s terrain, timeline, and safety needs. Making the right choice ensures smooth operations and cost-effective lifting from start to finish.

Safety and Regulations in Australia

Cranes in Australia are operated under strict safety laws and industry standards that protect workers, operators, and the public. These rules ensure every lift is planned, licensed, and carried out safely.

The two main Australian Standards that apply to crane operations are:

- AS 1418 Series: Covers how cranes, hoists, and winches should be designed and manufactured.

- AS 2550 Series: Outlines how cranes must be used, inspected, and maintained to stay safe and reliable.

Along with these standards, Safe Work Australia requires all crane operators, riggers, and doggers to hold a valid High-Risk Work (HRW) licence for their specific crane type, whether tower, mobile, or vehicle-loading.

Regular inspections are mandatory, including daily pre-use checks, yearly maintenance, and a full major inspection every ten years. Site teams must also follow Safe Work Method Statements (SWMS), set up exclusion zones around operating cranes, and ensure only trained personnel are allowed in lift areas.

Following Work Health and Safety (WHS) laws and Australian Standards is not just about compliance; it’s about keeping every site safe, efficient, and free from preventable risks.

Conclusion

Different types of cranes continue to shape how Australia builds and grows, from city towers in Sydney to regional bridges and major infrastructure. These various types of cranes make construction safer and more efficient on every site. Each crane type plays a vital role, designed to handle specific lifting challenges and support projects of every size. Understanding the different types of cranes enables construction teams to plan more effectively, work more safely, and deliver with precision.

Knowles Cranes focuses on providing safe, reliable, and efficient lifting solutions that meet every project’s needs. As construction technology advances, cranes will remain central to building Australia’s future, lifting stronger, higher, and smarter across every skyline.