How the Drop Deck Trailer Changed the Rules of Heavy Machinery Transport

We often stop to stare at massive machinery moving down the highway, wondering how such a giant load stays upright and secure. Most people don't realise that these heavy loads are specifically fitted onto these lowered platforms to ensure perfect balance and road safety.

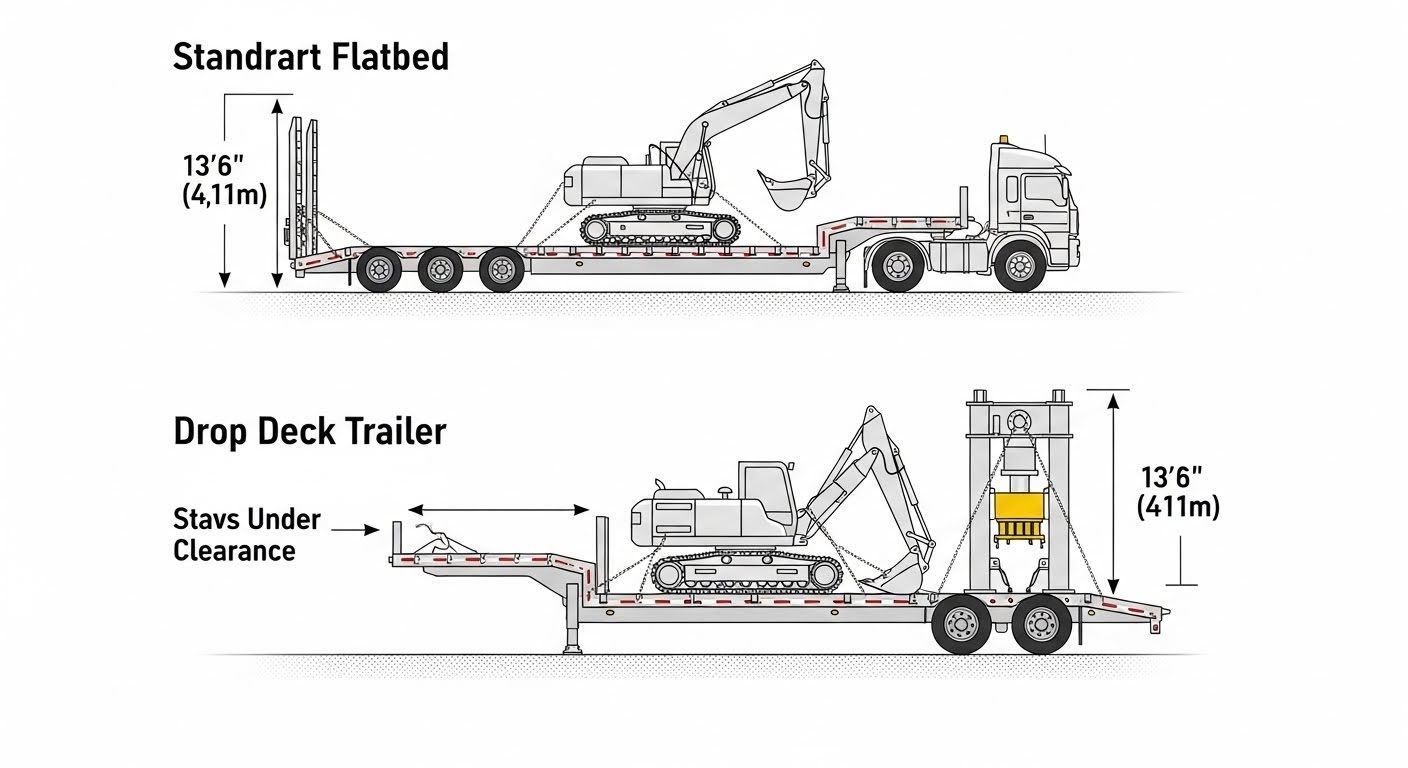

The main goal of this design is to lower the centre of gravity, keeping the cargo stable during every turn and lane change. This height reduction also allows oversized equipment to pass safely under bridges and power lines that a standard truck simply couldn't clear. It is the essential structural solution that makes transporting the world’s heaviest equipment possible.

Knowles Crane created this guide to explain why these trailers are the backbone of the hauling industry. In the sections below, we will break down their specific purpose, technical specifications, and the different types used to move the world's biggest machines.

What is the Purpose and Specialty of the Drop Deck Trailer?

The primary purpose of the drop-deck trailer is to overcome the physical limitations of standard transport. In a country where height is strictly regulated, the drop deck is a "legal loophole" engineered into a chassis. Its specialty lies in its ability to carry tall equipment, like harvesters, drill rigs, and site offices, without the cargo ever crossing the dangerous 4.3-metre height threshold.

The Specialty of the Step-Down Design

What makes this trailer unique is the 600mm step. By dropping the main deck closer to the road, the trailer specialises in two things:

Height Clearance

It provides an extra 650mm of vertical space, often the exact difference needed to clear an overpass without a pilot vehicle.

Stability Mastery

Because the heaviest part of the load sits lower, the trailer is specialised for the rough, unsealed roads found in the Pilbara or the Bowen Basin. This lower centre of gravity prevents "load sway," which is a leading cause of accidents in heavy hauling.

How the Drop Deck Trailer Broke All the Rules of the Road

Prior to the 1940s, the transportation of oversize machinery was a slow and tedious process. Contractors were forced to disassemble their oversize equipment, transport it in pieces, and then reassemble it at the construction site. The development of the removable gooseneck and drop centre trailer revolutionised the industry, moving away from the use of wooden ramps.

The 3 Rules That Were Broken by the Drop Deck

The Detour Rule

Traditionally, high loads had to be routed on detours of 100 km or more to avoid low bridges. However, the drop deck trailer has broken this rule by reclaiming as much as 650mm of vertical height. This means that machines such as excavators can remain below the 4.3-metre height limit, thus turning restricted routes into direct routes.

The Pilot Vehicle Rule

In some areas, anything above a certain height needs a costly pilot vehicle and police escorts. By lowering the height of the load, the company can avoid the rule altogether, thus saving an estimated 15-20% in logistical costs per trip.

The Stability Rule

The former rule regarding hauling on flatbeds indicated that high gravity loads were susceptible to load sway. The drop deck design with a 600mm step-down reduced the weight distance from the axles. This addressed the physics of stability, enabling heavy loads to move at highway speeds on rough terrain without the possibility of tipping over.

Choosing the Right Deck

Not every heavy load is the same, which is why the drop deck has evolved into several specialised configurations. Choosing the right one is a balance between the machine's weight and the ceiling height.

1. The Single Drop

It features a single step down behind the gooseneck, creating a long, low rear deck.

Best For: Tall equipment that is also very long, such as tractors, hay balers, or building materials.

The Advantage: It offers a massive amount of flat space while keeping the centre of gravity much lower than a standard flatbed.

2. The Double Drop

This is for the "extreme" loads. It has two drops: one after the gooseneck and one before the rear wheels, creating a "well" in the middle that sits just inches above the road.

Best For: Massive excavators, drill rigs, and industrial tanks that would be impossible to move otherwise.

The Advantage: It provides the maximum possible vertical clearance, allowing the tallest machines to pass under bridges that even a single drop couldn't clear.

3. The Extendable Drop Deck

For loads that break the rules on length and height. These trailers can literally slide apart to become longer.

Best For: Wind turbine blades, bridge beams, or long industrial pipes.

The Advantage: It offers the versatility of a standard drop deck but can be "stretched" to support oversized cargo that would otherwise overhang dangerously.

Maintenance & Safety

Because drop deck trailers carry high-value assets and operate closer to the road surface, they require a stricter maintenance schedule than standard flatbeds. Use this table as a guide for your safety inspections.

| Focus Area | Why It Matters | Key Inspection Action |

|---|---|---|

| Structural "Step" Points | The 600mm drop is a high-stress point where most weight is concentrated. | Perform visual or ultrasonic tests for hairline cracks in the high-tensile steel frame. |

| Undercarriage & Airbags | Low clearance (600mm-900mm) makes the trailer prone to bottoming out. | Check for scrapes or damage to brake lines, air tanks, and suspension bags. |

| Securement (D-Rings) | These points prevent "load sway" that can cause tipping accidents. | Monitor tie-down points for metal fatigue and ensure they meet the specific tonnage rating. |

| Tire Heat & Pressure | The smaller tyres on low-profile decks rotate faster and heat up quickly. | Monitor PSI levels and check for uneven wear caused by heavy, off-centre loads. |

Conclusion

The drop deck trailer did more than just lower a load; it raised the standard for the entire logistics industry. It turned what had been a high-risk gamble into a calculated, safe, and efficient science. By mastering the centre of gravity and outsmarting overhead restrictions, this engineering solution remains the invisible foundation behind our most ambitious infrastructure projects.

Knowles Crane can understand that every millimetre counts when moving the machines that build our future. In a world where machinery continues to grow in size and complexity, the rules will always be defined by those who can move the heaviest assets with the least amount of risk. The drop-deck trailer is why we can look at a massive piece of equipment on the highway and feel confident it is exactly where it belongs, perfectly balanced and ready for the job ahead.